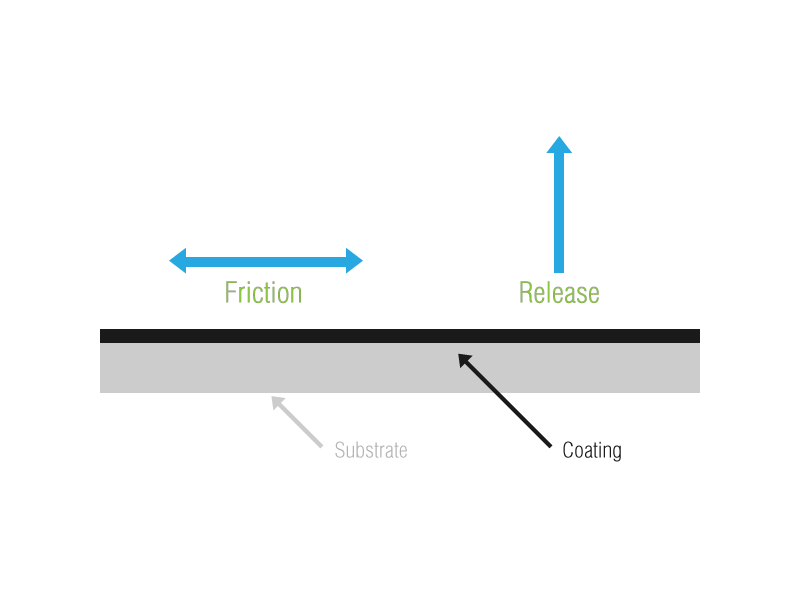

This is a result of the low surface energy that is a particular feature of fluoropolymers. Very few solid substances will permanently adhere to a fluoropolymer coating.

Low friction coatings typically have coefficients of friction varying from 0.05 – 0.2. This depends on the type of coating used and the load/speed involved.

Corrosion is a complex electrochemical process which can arise from a variety of sources. Galvanic corrosion and fretting can also cause component failure. Fluoropolymer coatings have been developed as highly effective solutions to problems caused by corrosion. Used as standalone systems or with additional sacrificial primers, we have a comprehensive range of coating systems on hand.

Fluoropolymers are broadly unaffected by most chemicals as a result of the strong carbon-fluorine bonds. The inert nature of these coatings provide huge benefits in reactive and corrosive environments.

Wear is inevitable when two surfaces rub against eachother. When friction is reduced, the rate of wear reduces as well. Blends of fluoropolymers and hard, durable resins can significantly reduce or in some cases eliminate wear altogether. Internally reinforced coatings are available that have ceramic or metallic fillers that can increase service life by up to five times that of a conventional low friction coating, with only a 20% increase in the coefficient of friction.

Fluoropolymer coatings have high dielectric strength, a very high surface resistivity and a low dissipation factor. Some formulations are available with metallic or carbon fillers to provide enough electroconductivity to enable dissipation of static.

Fluoropolymer coatings cannot be wetted. They are hydrophobic (water repellent) and oleophobic (oil repellent). As a result, coated surfaces are easier to clean and in some cases, the surfaces are self-cleaning.

Fluoropolymer coatings can maintain their physical properties at extremely low temperatures, even as low as -270⁰c.

Most coatings that contain PTFE and PFA can withstand continuous temperatures of 260⁰c and up to 290⁰c for short periods of around 30 minutes. Coatings that contain FEP are generally rated for maximum in-use temperatures of 205⁰c.

The majority of our coating systems are applied using conventional compressed air driven spraying techniques. The coatings are supplied as liquids and are decanted into either gravity fed or pressure fed spraying equipment.

Powder systems such as PFA and FEP are applied electrostatically, where the coating material (powder) and the part receive opposing electrical charges so that the powder will be attracted to the part. This is particularly useful where complex shapes are involved.

Fluoropolymer coatings can be applied to most solid materials as long as they are clean, dry and free from oils or silicone based substances.

The main limiting factor with substrate materials is the temperature that the part can withstand. The vast majority of fluoropolymer coatings need to be cured at an elevated temperature. Most coatings are cured between 220⁰c and 420⁰c, depending on the type of coating system selected. Some coatings designed for flexible finishes can be cured as low as 80⁰c.

Almost all metals can be easily coated. Copper and other alloys such as brass and bronze with a high copper content can cause issues. Copper will oxidise at the elevated curing temperatures and form an oxide layer between the substrate and the coating. In such circumstances, a layer of electroless nickel will stop any copper oxide forming on the surface. Some high nickel alloys can also present adhesion issues but effective blasting is normally a good solution.

Many plastics can be coated but the system has to be carefully selected as solvents can attack plastics and physical properties can be affected by curing temperatures. Pre treatments are available for temperature sensitive substrates which are particularly useful where grit blasting would affect the integrity of the substrate.

Some rubbers and elastomers can be coated, such as EPDM, HNBR, NBR amongst others.

Ceramics and glass can be coated. Due to the nature of these substrates, there are limited opportunities to prepare the substrate with a key, but coating systems that are loaded with highly adhesive resin systems can be used to great effect.

Carbon fibre and composite materials are increasingly being used and the unique properties of such materials can be further advanced by the application of a non stick or low friction coating. We have seen increasing demand for this type of service where tangible benefits have been gained, particularly in the motor racing industry where discarded tyre rubber and track debris can have significant effects on aerodynamic performance.