In most cases, the coatings that we apply will provide a finish that is low in surface energy. Such a finish will give good non-stick and release properties. This is the main characteristic of the coating layer, when it is cured.

Non stick and release properties are not to be confused with low friction values. Friction is a measure of the resistive force opposing two objects sliding against each other. Non stick/ release, or low surface energy values are a result of intermolecular forces.

When we apply our coatings, we need a substrate with high surface energy and a coating, as applied, with low surface tension so that the coating will ‘wet out’ on the surface and spread out into a uniform film without forming into beads or small droplets. This is achieved by adding surfactants to the coating solution which are driven off during flash-off and cure. The best method of increasing the surface energy of the substrate to overcome the surface tension of the coating solution even more, is to apply a profile to the substrate using abrasive blasting media. This will also provide a mechanical ‘key’ for the coating to adhere to.

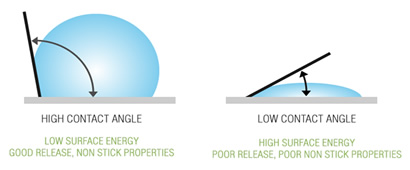

We can establish how effective non-stick and release characteristics are by measuring the contact angle of a bead of water on a coated surface. Water molecules have strong attractive forces which result in a relatively high surface tension, giving the tendency of a droplet to ‘ball up’ into a spherical bead.

On a low energy surface (good non-stick, good release, non-wetting) the water will not be able to wet the surface and the surface tension will result in a high contact angle. When the surface energy is high (poor release, poor non-stick, good wetting) the droplet will tend to flatten out with a low contact angle.

We can also use this principle to determine how effectively a coating system may adhere to a substrate. In this instance, optimum wetting and adhesion of the coating material would be achieved when the bead contact angle is as low as possible, indicating a high level of surface energy.

Within the droplet of water, all of the molecules are surrounded by other water molecules and the forces between them are in equilibrium. It is only at the interface between the air and the water that the water molecules are being attracted by the surrounding water molecules and not by the air. The imbalance of the forces allow the droplet to attempt to form a spherical bead – surface energy permitting!

A further indication of release and non-stick properties is how the bead of water behaves when the part is tilted at an angle. When the part is tilted at an angle of around 10⁰, if the bead rolls away and maintains its shape, the non-stick and release properties are excellent. If the bead drags and forms a tail or breaks up, the non stick and release properties will not be quite as good.

Amongst our portfolio of coating systems, we have solutions that are appropriate for the vast majority of applications. Fluoropolymer coatings can offer lower cycle times, increased yield, reduced energy costs, elimination of release agents and improved product quality.

Our experience unlocks a huge choice of options for even the most challenging of applications. Please contact us to discuss your requirements by telephone on 01798 343586 or email our Sales department sales@ptfecoatings.com.